Company News

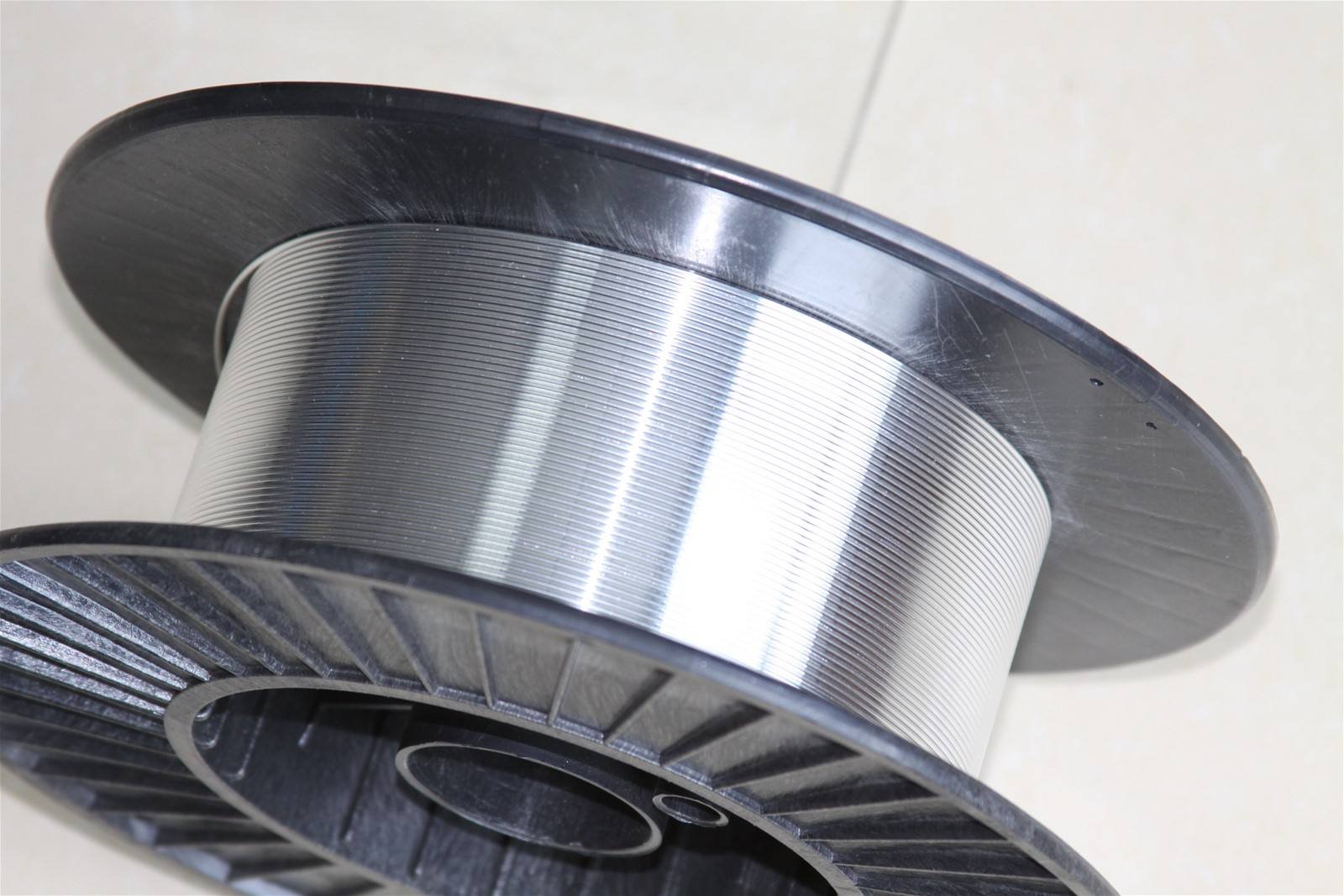

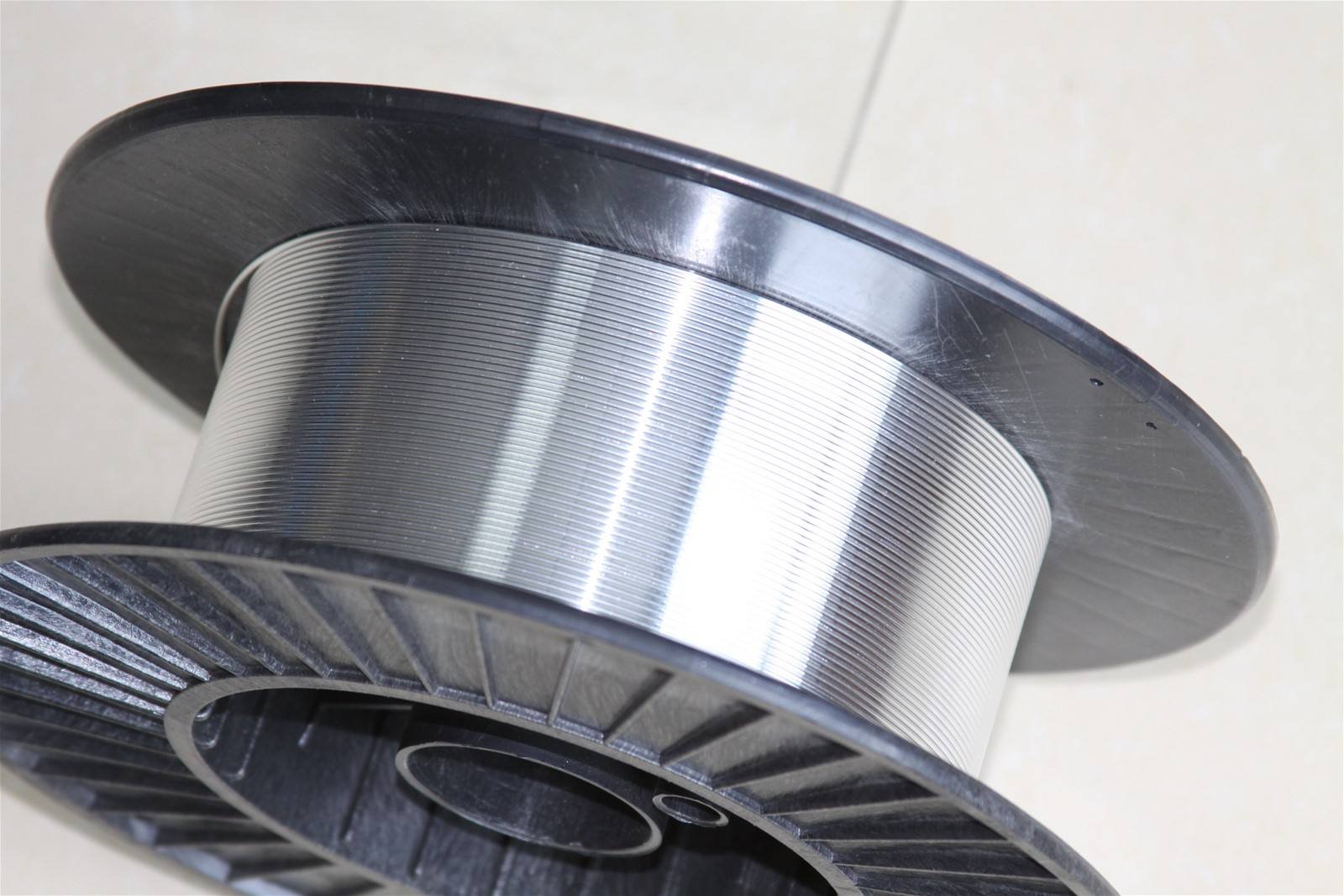

5183 aluminum magnesium alloy welding wire

Editor :frank

Time :2020-01-02 17:46

5183 aluminum-magnesium alloy welding wire contains 5% magnesium alloy welding wire. This series of aluminum alloy welding wire is a versatile welding material suitable for welding or surfacing 5% magnesium cast and forged aluminum alloy with high strength and forgeability. Well, it has good corrosion resistance. Aluminum alloy wire can also provide good color matching for anodized welding.

Typical chemical composition of 5183 aluminum-magnesium alloy welding wire: Mg 5, Cr 0.10, (Fe + Si) 0.3, Cu ≤ 0.05, Zn 0.05, Mn 0.15, Ti 0.1, AL balance.

5183 aluminum-magnesium alloy welding wire uses: bicycles, aluminum scooters and other sports equipment, locomotive compartments, chemical pressure vessels, military production, shipbuilding, aviation and other industries.

5183 aluminum welding wire should be selected from

First, the crack sensitivity of the weld metal: choosing a filler metal with a melting temperature lower than the base metal can greatly reduce the tendency of intergranular cracks in the heat affected zone. Therefore, welding wire with an alloy content higher than that of the base material is used as the filler metal, which can generally prevent weld metal cracks.

2. Joint strength: The strength of the welded joint changes with the alloy element content of the welding wire. That is, the strength of weld joints of non-heat-treated alloys increases in the order of 1000 series, 4000 series, and 5000 series.

3. Color difference after anodizing treatment: In order to improve the corrosion resistance, anodizing treatment is often performed after welding. If the composition of the weld metal is significantly different from the base metal, or the casting structure of the weld metal is different from the rolled structure of the base metal, Weld metal produces chromatic aberration after anodizing.

4. Mechanical properties and corrosion resistance of joints under high temperature: 5000 series welding wires (5654, 5356, 5556, 5183) containing more than 3% magnesium should be avoided in structures with a temperature above 65 degrees Celsius, because these alloys have stress corrosion Cracks are sensitive and stress corrosion cracking can occur in the above temperature and corrosive environment.

5. Workability of joints: Welded joints that require bending, generally workability is affected by plasticity, and plasticity decreases with increasing strength

Typical chemical composition of 5183 aluminum-magnesium alloy welding wire: Mg 5, Cr 0.10, (Fe + Si) 0.3, Cu ≤ 0.05, Zn 0.05, Mn 0.15, Ti 0.1, AL balance.

5183 aluminum-magnesium alloy welding wire uses: bicycles, aluminum scooters and other sports equipment, locomotive compartments, chemical pressure vessels, military production, shipbuilding, aviation and other industries.

5183 aluminum welding wire should be selected from

First, the crack sensitivity of the weld metal: choosing a filler metal with a melting temperature lower than the base metal can greatly reduce the tendency of intergranular cracks in the heat affected zone. Therefore, welding wire with an alloy content higher than that of the base material is used as the filler metal, which can generally prevent weld metal cracks.

2. Joint strength: The strength of the welded joint changes with the alloy element content of the welding wire. That is, the strength of weld joints of non-heat-treated alloys increases in the order of 1000 series, 4000 series, and 5000 series.

3. Color difference after anodizing treatment: In order to improve the corrosion resistance, anodizing treatment is often performed after welding. If the composition of the weld metal is significantly different from the base metal, or the casting structure of the weld metal is different from the rolled structure of the base metal, Weld metal produces chromatic aberration after anodizing.

4. Mechanical properties and corrosion resistance of joints under high temperature: 5000 series welding wires (5654, 5356, 5556, 5183) containing more than 3% magnesium should be avoided in structures with a temperature above 65 degrees Celsius, because these alloys have stress corrosion Cracks are sensitive and stress corrosion cracking can occur in the above temperature and corrosive environment.

5. Workability of joints: Welded joints that require bending, generally workability is affected by plasticity, and plasticity decreases with increasing strength

Related :

- 180 Grade Self Bonding Enamelled aluminium Wire2013.12.19

- 1050 1350 Bunched Aluminium Wire2013.12.19

- Industrial Pure Cold Drawn Aluminium Wire Cable 1352013.12.19

- Deoxidized round aluminum rods2013.12.19

- The role and practical application of coiled alumin2013.12.19